How It’s Made

Painting the Best Rods on Earth

March 17, 2023

The finish on a St. Croix rod reflects the pride St. Croix Team Members take in making it, as well as the pride you’ll take in using it. Over 30 different paints are used to finish blanks in the current St. Croix Rod lineup.

“The paint we use is a proprietary formula with a variety of special flex additives, which allow the paint to flex with the blank so it doesn’t chip or flake when the rod goes under load,” says St. Croix Engineering Assistant, Ed French. “Some of our paints have metallic or pearl flake and some are more translucent than others depending on the type of finish desired by the Product Team.”

A beautiful finish on any rod blank begins with sanding and surface prep. Sanding ensures the blank surfaces are mirror smooth. Too much sanding can damage the carbon fibers and weaken the rod’s integrity. After sanding, blanks are thoroughly scrubbed with a mild dish soap, rinsed with clean water, they wiped down with 99% Isopropyl alcohol to remove any residual dust or contaminants.

French says St. Croix employs two different painting processes, the squeegee process and the electrostatic spray process. The rod series and the paint determine which process is used.

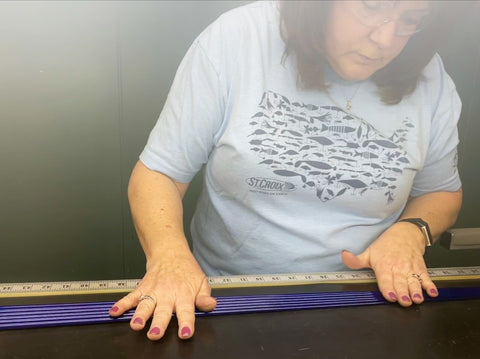

“The squeegee process applies a uniform coat of paint by passing a rod blank through a circular opening in a rubber membrane,” French says. “The opening ranges in size from .06” to .23”, and the process is completed by hand.” A reservoir filled with paint lies behind the rubber membrane. The paint technician carefully controls the angle at which the blank is pushed into the membrane and through the paint behind it, as well as the angle and speed at which the blank is drawn back through the paint and membrane during the return stroke.

For rods that are sprayed, French says St. Croix converted from HVLP (high volume low pressure) spray to an electrostatic spray process last year. “In St. Croix’s state-of-the-art, computer-controlled electrostatic spray booths, the blanks are placed onto a stud which grounds the blank. A turbine applies a negative charge to the paint particles which are attracted to the grounded blank as they exit the spray nozzle.” French, says both spray processes can produce a beautiful finish, but the electrostatic process is much more efficient. “Our transfer efficiencies increased from about 27% with the old HVLP system to about 85% with the new electrostatic process,” French says. “That means we’re painting rods faster, using significantly less paint, greatly reducing the amount of VOCs in the environment, and changing our filters less often. The quality and consistency of the finishes generated by the electrostatic system are also superior, because we don’t get the overlaps that could occur with the old HVLP system.”

Once painted, each rod blank is hung vertically on a drying conveyor which proceeds slowly into a drying oven where they spend 27 minutes to cure the finish at 235 degrees Fahrenheit. Humidity is also carefully controlled and monitored.

Painted rod blanks are carefully inspected after drying. Skilled inspection technicians look for a uniform and flawless finish. Blanks that reveal thin spots, runs, drips, contaminants, or any other flaws or inconsistencies are rejected.

Like everything else done at the St. Croix factory, the blank-painting process relies on an essential combination of cutting-edge technology and human skill. The result is flawlessly beautiful rod blanks that go on to become adorned with guide trains, handles, reel seats and other componentry that completes the Best Rods on Earth. Want to see every step of how our dedicated team handcrafts your St. Croix rods? Come see us in Park Falls, Wisconsin and take a factory tour.